When the factory moves into cyberspace

“We are now facing the fourth industrial revolution with smart factories where both products and machines are connected to the internet and communicate,” says Camilla Niss, researcher at the University of Gävle.

Cyber-physical systems

The next step in this fast development is that is called “The Internet of Things” and cyber-physical systems, where products and systems are connected and interconnected.

This type of collaborative systems will dominate society and make their mark on everything; there will be intelligent buildings and houses, smart energy systems and transportation, health care and laundries.

Camilla Niss explains that it is assumed that digitalisation will change manufacturing fundamentally, since both products and machines will be connected to the internet and communicate.

Suppliers will become key players

A research team at the the University of Gävle intend to investigate how the constant increase in digitalisation affects different industrial suppliers and their ability to contribute to innovation in industrial companies.

“When companies are to develop their products or processes, for example develop a new car or improve their production line, they tend to look for knowledge outside their own organisations. This is called open innovation.”

In this way, customers, suppliers and even competitors contribute with new knowledge, for instance regarding the development of a new car engine or on how to optimise the manufacturing process.

Supplier 4.0

Since open innovation is becoming more common, it is very important that supplier can contribute to the process of innovation.

“There is very little research that takes a supplier perspective. We are going to look at what organisational and technical skills the suppliers need to be able to contribute to the innovation of a company."

The concept “supplier 4.0” designates a supplier who has developed the ability to contribute to an industrial company’s innovation in an increasingly digital context.

The whole world is investing

Camilla believes that the degree of digitalisation will increase substantially and that it is essential that Sweden invests in education, research and the business sector to be able to use this new technology. We need to be alert.

“The whole world is investing in digitalisation, and this is a project in which we can contribute in a concrete way by developing knowledge on how companies can become competitive,” Camilla Niss says.

Millions to a research team at the University

Researchers at the Centre for Logistics and Innovative Production (CLIP) at the University of Gävle have been awarded 2,96 million SEK by Lars Erik Lundberg’s foundation for research and education.

Project leader is Senior Lecturer Camilla Niss and together with her colleagues Docent Robin von Haartman and Professor Lars Bengtsson she will investigate how increased digitalisation and more open innovation processes can affect different industrial suppliers’ ability to contribute to the innovation of industrial companies.

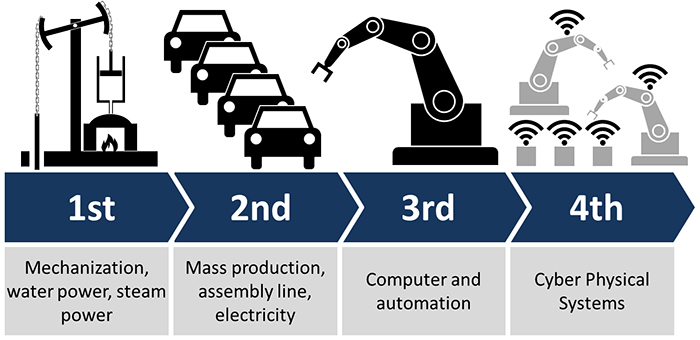

Industrial revolutions

- The first one was the industrial mechanisation that was brought about by the steam engine at the end of the 18th century.

- The second one started at the beginning of the 20th century and involved division of labour, specialisation, mass production and assembly lines.

- The third one came about during the 1960s when the information society had its breakthrough and robotics with automation and automatisation.

- Now, the fourth industrial revolution is a fact, and, to a large extent, it concerns what is referred to as cyber-physical systems and the Internet of Things, when both products and machines are connected to the internet and communicate.

For more information, please contact:

Camilla Niss, researcher in industrial engineering at the University of Gävle

Tel: 026-64 88 01, 073-460 98 90

Email: camilla.niss@hig.se

Text: Douglas Öhrbom

.png) Print

Print

Utskriftsversion

Utskriftsversion